Condition Monitoring & Troubleshooting Service

HEAD OFFICE

(+47) 70 14 45 00

08:30 TO 16:30

MONDAY TO FRIDAY

Lerstadvegen 545, 3 et.

ÅLESUND, 6022 NORWAY

ONLINE CONDITION MONITORING SYSTEM

Advanced online solution for

Asset performance & condition monitoring

CM+ is 24/7 online system for continuously condition monitoring, data recording and risk analysis. CM+ supports a wide range of rotating equipment and structures

CM+ created with advanced technologies to

- Reduce repair time and costs

- Avoid revenue loss

- Save maintenance cost

- Increase plant life

- Improve safety assurance

- Reduce personnel risk

- Reduce risk for mechanical breakdown

- Improve plant design and profitability

CM+ applications areas:

- Oil & Gas

- Vessels

- Wind energy

- Hydro power

- Industries

CM+ offering a network based distributed system for advanced online machinery monitoring and data recording where vibration is the primary monitoring parameter.

Main system features:

- Band based vibration level measurements

- Real-time monitoring

- Transient signal detection

- Machine load signal utilization

- Run-up, slowdown, periodic and on-alarm signals recording

- Dynamic alarm limits

- Historical data trending

- Trend level prognosis

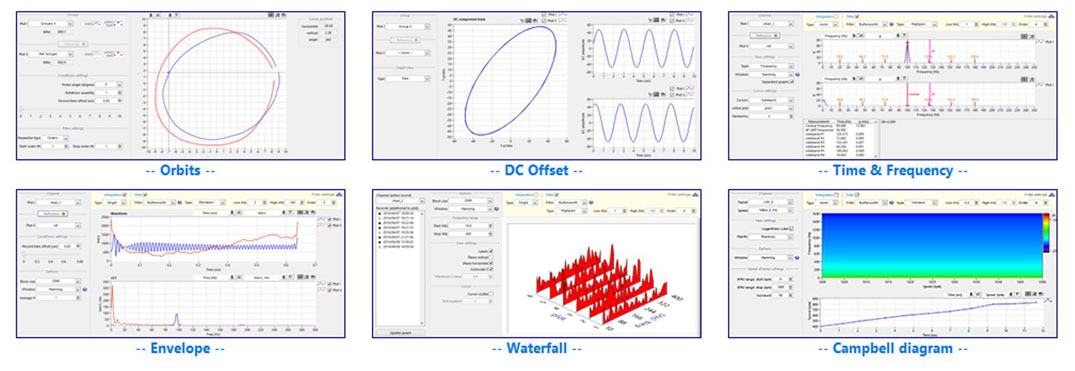

- Advanced frequency analysis of recorded data

- Advanced data filtering

- Orbit monitoring

- Periodical statuses and reports

- Web interface to on-line and historical data

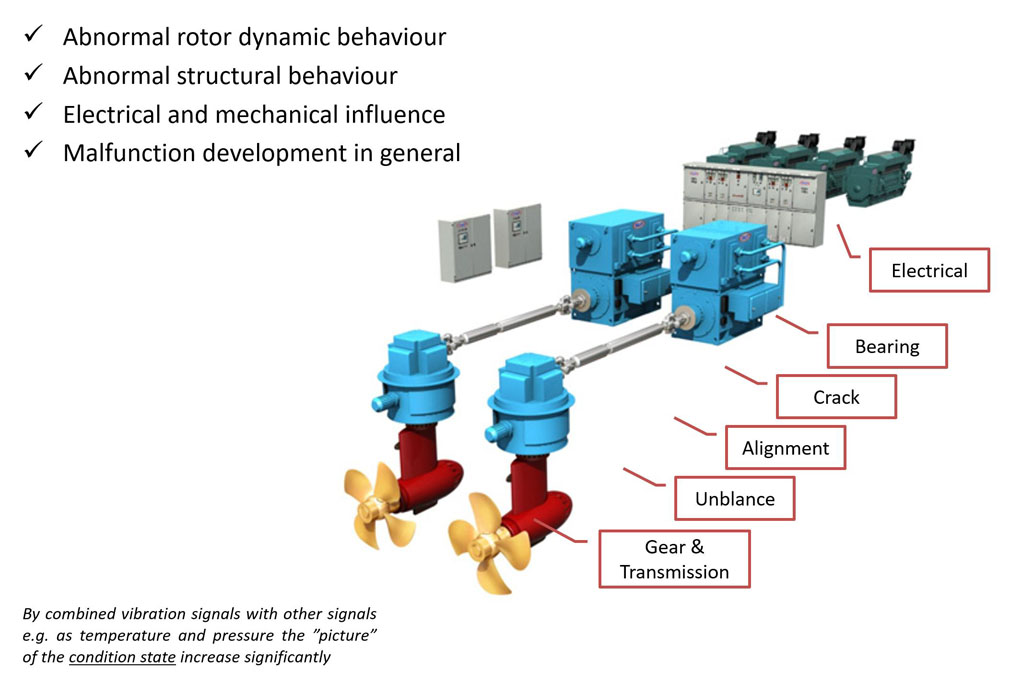

CM+ detects and predict many types of failure:

- Bearing malfunctions

- Alignment status

- Unbalance problems

- Crack detections and malfunctions

- Abnormal rotor dynamic behaviour

- Abnormal structural behaviour

- Malfunction development in general

CM+ system supports signals from different kind of sensors and transducers:

- Accelerometers

- Velocity probes

- Displacement probes

- Pressure and flow sensors

- Thermocouples

- Humidity sensors

- Proximity probes

- Strain Gauges (stress and strain)

- Tachometer/speed sensors

- Microphones

- General current and voltage sensors

Advanced options:

- Easy integration with other systems

- Remote support and software updates

- Fast integration of the extra requirements

- Further rapid modifications by request

Condition Monitoring vs Traditional maintenance strategies

The traditional maintenance strategies of “Run to Failure” and “Scheduled Maintenance” are increasingly unacceptable in many process and manufacturing operations. The alternative, to use Condition Monitoring systems (CMS) with predictive capabilities, provides early detection of machinery problems based on collection of machine data. Lower machine maintenance costs and higher availability result when systems are properly installed within a suitable maintenance regime.

Maintenance schedules are generally derived from a conservative viewpoint which often results in regular strip-down and component replacement, even though it may not be necessary. Unnecessary machine overhauls - intended to prevent future faults developing - often do more damage than allowing machines to run without overhaul. This “preventive maintenance” is costly in downtime and spares requirements. Since it does not prevent failures consistently the alternative title, Scheduled Maintenance, is a more apt description.

A more logical strategy would be to identify developing faults (including machine wear) by monitoring the condition of a machine in service. CM is the cornerstone of a predictive maintenance programme which complements scheduled maintenance, enabling longer intervals between routine overhauls. Suitable CM equipment minimises unnecessary maintenance activity and reduces the costs of repairs by detecting fault symptoms before serious damage occurs. However, CM does require investment in equipment and operational resources before returns on the investment are realised as bottom line savings on the maintenance budget.

Condition Monitoring is a generalised method of establishing a machine's health using measured parameters which reflect changes in the machine's mechanical state. Regular monitoring of the mechanical condition of machine trains and the operating efficiency of processes provides data to determine maximum safe operating intervals between overhauls.

CM+ VIDEO PRESENTATION

CM+ ADVANTAGES

MORE DETAILED INFORMATION

Types of failure to detect

Example of the sensors installation

CM+ hardware/software structure

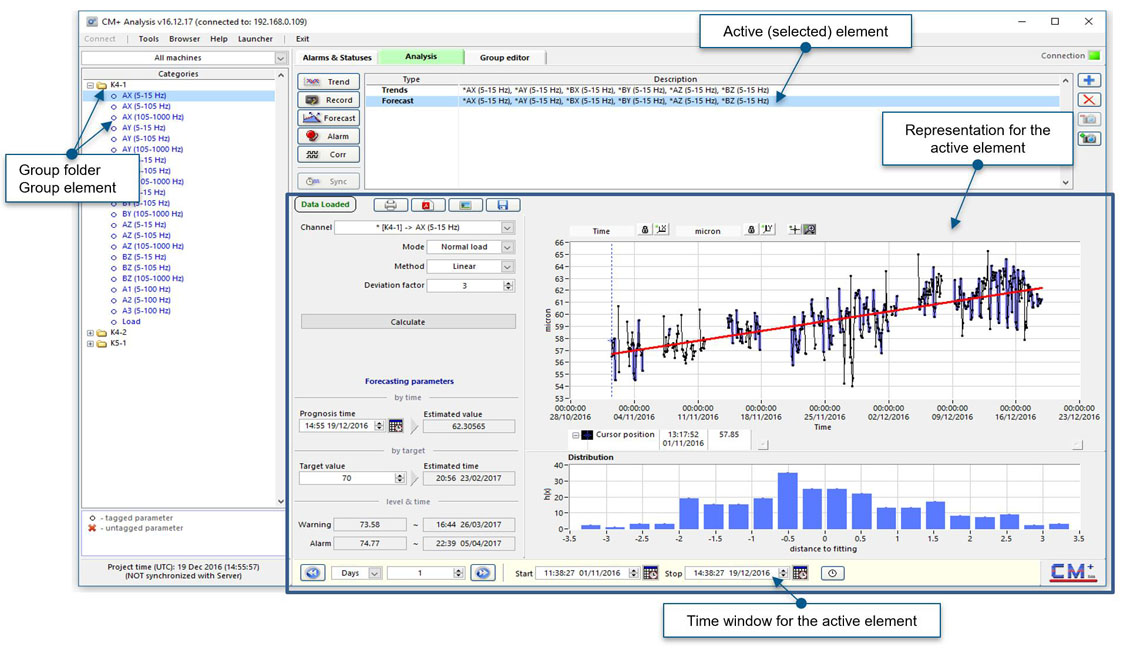

CM+ software examples

Real-time monitoring

In this mode the Narrow Band Monitoring (NBA) parameters can be monitored and analyzed in real-time, both color coded parameter status and values. Each single NBA object is a narrow band frequency parameter, where the frequency range, alarm limits, real-time values and trends are available in a single screen view. The monitored system and machines with all measuring points and NBA parameters are also available on the left side of the screen in a typical hierarchic windows structure.

Example of analysis software

Maintenance and service planning is always important and often crucial activities for all kind of industrial plants and technical installations in general. But to be able to prepare and make effective service and maintenance plans, forecast analysis is always an important part of any condition monitoring system to be able to predict when condition degradation and fault development will require service activities should take place. Forecast analysis is available for every single analysis parameter and can be used selectively for all kind of defined load conditions. Alarm limits for the parameter in question are also available together with alarm limit prognosis.

Some examples of the analysis methods

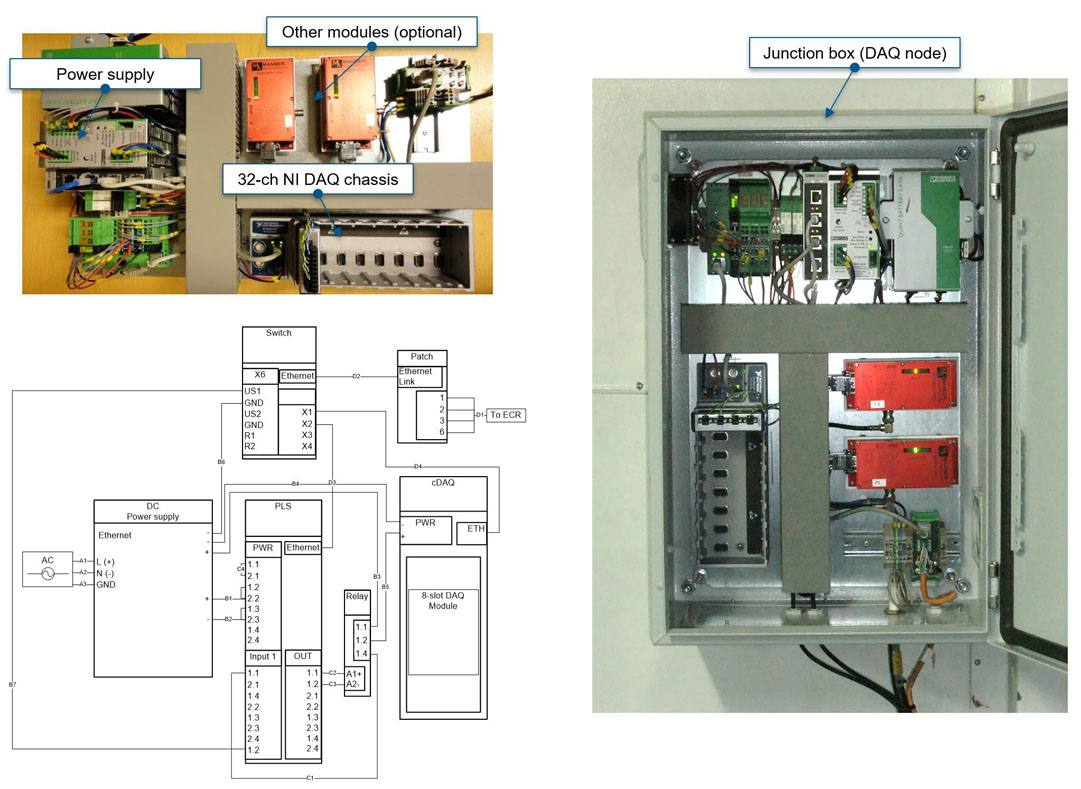

CM+ daqClient Node installation example

Communication with other systems

CM+ can provide any kind of real-time measured/processed data (such as band value, alarm statuses, etc.) via Modbus Ethernet protocol.